INSTASCAN COATING SYSTEM

Non-destructive Testing / Thermal Mapping

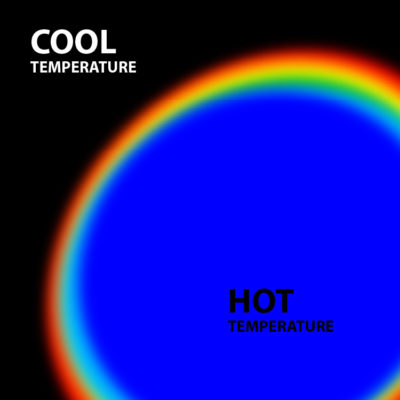

Instascan Coating System is a two-part coating system that will change color with changes in surface temperature originally developed for Non-Destructive Testing (NDT) of large area composite, laminated, and honeycomb structures.

- Surface and Sub-Surface Flaw Detection in Metals, Welded Metals, Bonded and Other Composite Structures

- Thermal Gradient Visualization of Temperature Fields

- Aerospace and Engineering Research

- Heat Transfer Studies

- Electronic Component Testing

- Simple Application; brushing, roller coating, spraying, or using hand or automated equipment

Instascan Black Base Coating

Instascan Black Base Coating is a black water-based pigmented coating designed for use as an undercoat to enhance adhesion and intensify the thermal response (color change properties) of the liquid crystal coat, which is applied over it. Application can be by brushing, roller-coating or spraying using hand or automated equipment. Ideally, the coating should be applied uniformly to completely cover the test surface. It can be thinned by adding distilled water and mixing well. Removal can be accomplished easily by washing with water and mild detergents.

Instascan Liquid Crystal Coating

Instascan Liquid Crystal Coating is a temperature-sensitive water-based coating containing a microencapsulated cholesteric liquid crystal mixture with a color play response in the temperature range of 32-35ºC. It is designed to be applied as an overcoat on top of the Black Base Coat. Liquid Crystal Coating also contains black pigment. Application can, again, be by brushing, roller-coating, or spraying using hand or automated equipment. It can also be thinned by adding distilled water followed by thorough mixing. For optimum color response the coating should be applied uniformly and in sufficient amounts to give a dry film thickness of approximately 2 mils (50 microns). This is equivalent to coverage of approximately 2.5 – 5.0 m2 per KG (100 -200 ft2 per US gallon). The product can also be removed by washing with water under pressure. Detergents can be added to the water to enhance clean-up.

INSTASCAN NDT FEATURES

- Water Based

- Simple Application

- Easily Removed

Instascan NDT Applications

- Metals, Welded Metals, Bonded, and Other Composite Structures

- Aerospace and Engineering Research

- Heat Transfer Studies

- Electronic Component Testing

- Simple Application; brushing, roller coating, spraying, or using hand or automated equipment

Description Undercoat

Black Water Based Pigment Designed to Enhance Adhesion and Thermal Response

Description Overcoat

89°F to 95°F

Product Chart

| # | Description | Size | PDS | SDS | |

|---|---|---|---|---|---|

| 8202DA | Black Base Coat | Gallon | 079 | 065 |

| 8202DBFF | Liquid Crystal Coating | Gallon | 079 | 066 |